In November, the University was awarded over £3.4 million in funding to deliver a range of carbon reduction projects across its UK campuses. The funding comes from 3 different grant awards from Salix Finance, financed by the Department for Business, Energy and Industrial Strategy (BEIS):

- £3.3 million from the Public Sector Decarbonisation Scheme

- £120,000 from the Low Carbon Skills Fund to cover additional resource to support delivery the main grant funded projects

- £45,000 from the Low Carbon Skills Fund to cover low carbon heating feasibility studies for 6 buildings

These projects are anticipated to reduce our annual carbon emissions by almost 900 tonnes CO2, saving £400,000 per year. This article provides an overview of the projects the University is delivering with these grant awards.

Carbon Reduction Projects

Catering Oven Upgrades

Catering Oven Upgrades

All of the ovens in our Catering outlets have been replaced with more modular, energy efficient models, saving space as well as energy. We are currently monitoring the energy savings of the new units, with savings of up to 70% anticipated. The new ovens are all electrically powered, replacing many gas appliances, which will support our decarbonisation targets for the future.

Lab refrigeration upgrades

Lab refrigeration upgrades

Over 60 fridge/freezer appliances have been replaced in our science labs. The previous models were extremely energy-hungry, particularly our Ultra-Low Temperature freezers; each costing £1,200 annually to run. Some of these appliances were over 30 years old!

Lab drying oven upgrades

Lab drying oven upgrades

We replaced many of the drying ovens used in the labs with new, energy efficient models. Most of the previous drying ovens were over 30 years old, with poor insulation and minimal controls. Savings of over 60% in electricity demand are anticipated, including through reducing overheating in the labs.

Due to the good expected energy savings of the new appliances through the Salix grant, we have decided to also replace the remaining drying ovens not covered by the Salix grant from internal funds.

Farms refrigeration upgrades

Plans have been made to replace a large external refrigeration unit at CEDAR Farm with a new built for purpose unit.

We will also be replacing two of the Ultra-Low Temperature freezers at CEDAR Farm with new, energy efficient models.

Lighting

Over 5,000 lights will be replaced with LED’s in buildings across all three of our campuses, with the majority of work taking place on the Early Gate side of Whiteknights Campus. Moving to LED lights will generate up to 70% in energy savings.

We will also be replacing the stage lighting in the Minghella studio. We estimate this will make an 85% energy saving. Replacing the lights will also reduce overheating, meaning less energy will also be required to cool the building.

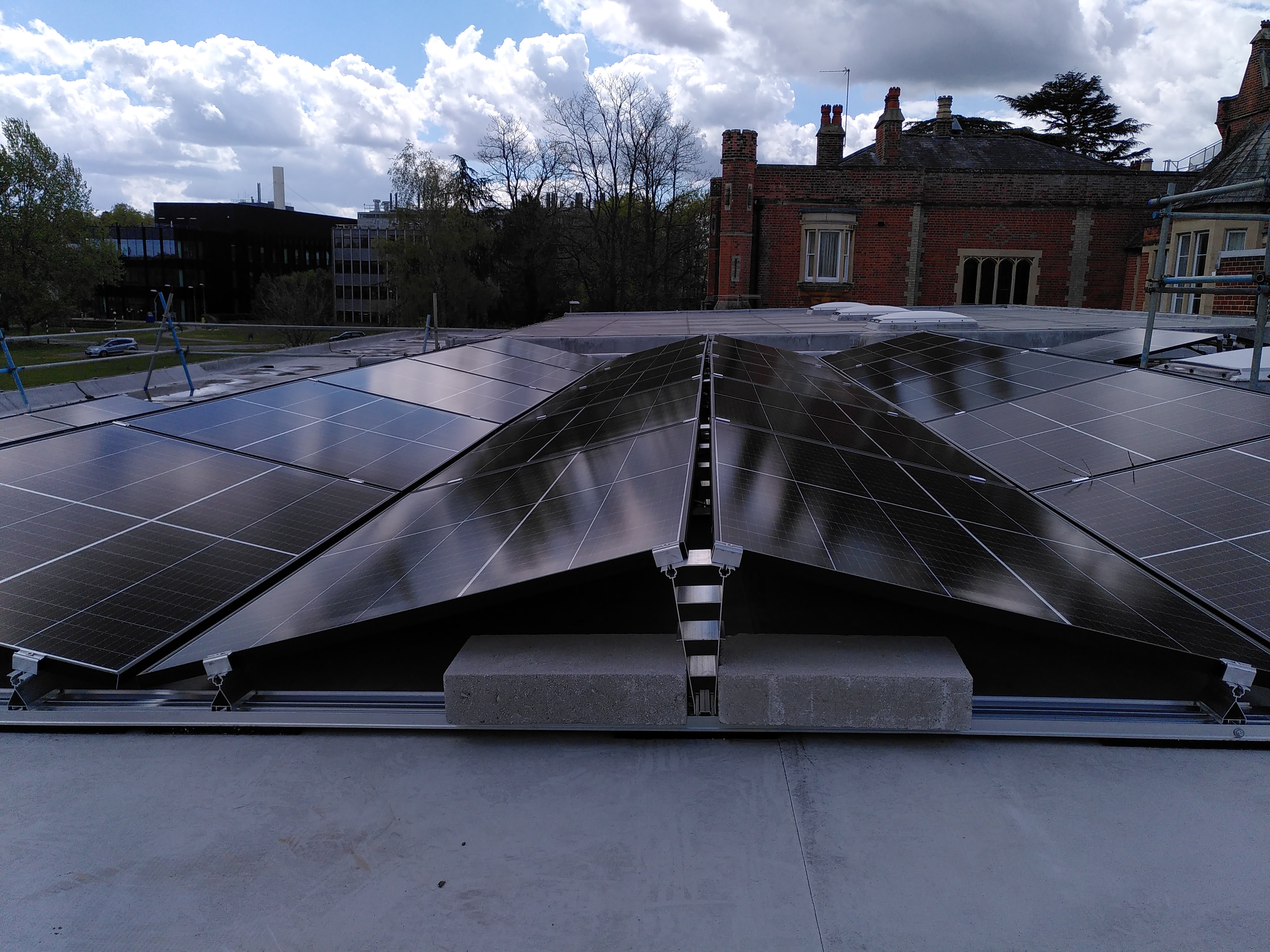

Rooftop PV Installations

Rooftop PV Installations

Over the upcoming months, we will be installing photovoltaic (PV) panels onto 9 further buildings across Whiteknights campus. Once these projects are complete, over 2,000 additional panels (732 kWp) will have been added to our generation capacity, quadrupling Whiteknights’ current capacity!

If you have had the opportunity to visit Whiteknights campus this month, you may have spotted that work is currently underway at RUSU and JJ Thomson. These 2 buildings alone will double Whiteknights’ current generation capacity.

Ventilation control upgrades

We will be installing additional temperature and CO2 sensors in several buildings on Whiteknights campus, enabling us to monitor ventilation systems more closely, which helps to prevent energy wastage.

Ventilation system improvements

We will install new energy efficient motors and improved controls into several of our ventilation systems to provide energy saving interventions. In some spaces, the upgrades will save up to 40% in energy demand. In the Palmer building, we will replace the entire ventilation system for one of the lecture theatres.

Air conditioning replacement

We have identified some ageing, oversized air conditioning systems (one was 339% larger than required!) which will be replaced with more efficient, appropriately sized systems.

Metering

We will be installing additional gas and electric meters into several buildings. Installing more meters allows us to understand where our energy goes – this can help us identify areas where there may be unexpectedly high energy usage, for future energy saving interventions.

Pipework insulation

We will improve pipework insulation in a number of buildings in order to prevent energy wastage. Of particular interest is the Harry Nursten building, which has a lot of pipework running around the internal perimeter of the building, causing overheating. Insulating this pipework will reduce overheating and simultaneously reduce energy costs required to cool the building.

Heating pipework improvements: Greenlands Main House and URS building

We will significantly improve the heating controls in these buildings so that we can provide more localised heating to the spaces that need it. Currently, Greenlands Main House has one heating zone – while different areas within Greenlands Main House have specific heating needs, we cannot turn the heating on/off in these areas at different times. Similar issues will be addressed in URS, where there is also the added problem of areas being either too hot or too cold in the south-facing and north-facing areas of the building.

In Essence, by improving the heating controls, we can create different ‘zones’ in these buildings which can be controlled separately, saving significant amounts of energy (and money!).

Greenlands Main House Electrical Capacity Upgrade

We will be increasing the electrical capacity at Greenlands, Henley Business School so that we can prepare to install a low carbon heating system in the future. We have long been considering a low carbon heat pump solution for Greenlands, and this is an important step in the right direction.

Low carbon heating feasibility studies

Feasibility studies have been undertaken at 4 specific sites to examine the potential to retrofit a low carbon heat pump to replace the gas heating system. The sites were: SportsPark, CEDAR Farm (2 sites) and the Estates building. In addition, the potential to connect the heating and hot water systems in Archaeology and Chemistry respectively have been investigated, with the Chemistry connection now in the process of being commissioned.

These feasibility studies provide some useful learnings which will help us develop our decarbonising plans further in the future. At SportsPark in particular, we hope to progress the design of a new heating system in 2021/22.